|

General information Main technical specification The main features and possibilities of software Results obtained on Solver-P7LS |

|

Solver-LS AFM provides CD and DVD discs manufacturers with the improved methods to analyze the quality of the stamper and disc surfaces. AFMs produced by NT-MDT are perfectly suited to the investigation of bump and pit characteristics in DVD and CD manufacturing. One of the major advantages of AFM mode over other techniques is that AFM provides quantitative, three-dimensional imaging of the disc or stamper surface within minutes. And once an AFM image is captured, cross-sections can be obtained in seconds to provide pit depth, pit width, pit side-wall angle, and track pitch anywhere in the data set - and without physically damaging the disc. The discs may be examined before metallization and after molding for pit characterization with Solver AFM. The following types of measurements can be provided for CD and DVD inspection using Solver-LS AFM:

The following of Disc Problems can be analyzed with Solver-LS AFM: |

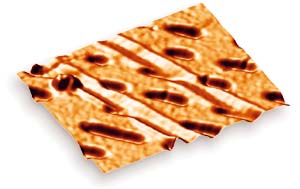

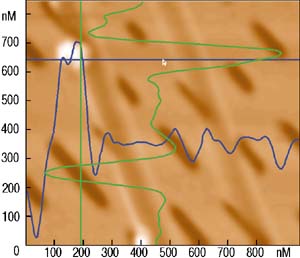

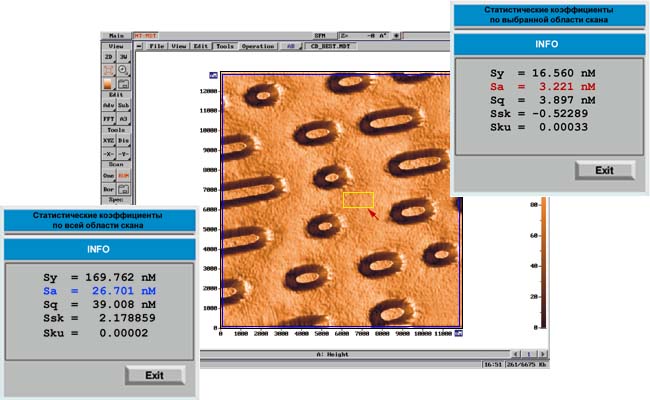

Scan size: X:10.5um, Y:8.4um, Z:0.25um |

|

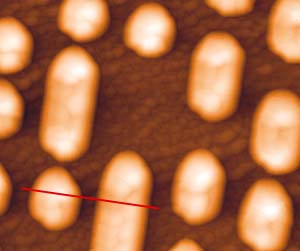

| The whole surface of wafer can be previewed through optical system to determine the defect area. The located stamper area with defects is scanned to visualise and determine the cause of these defects. |

SFM image of CD Al cover of Replicated disk. |

|

|